Orifice Meter Run

Orifice Meter Run

EMI offer an extensive range of orifice meter run products. Precision components are manufactured from a main central CNC Hub offering faster, precise and high quality finished products.

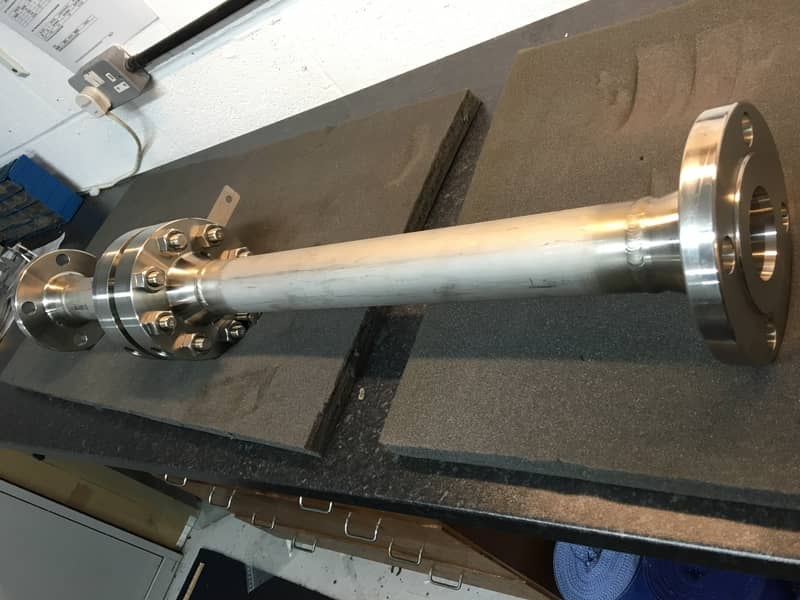

Orifice Meter Runs are easily introduced into fluid and gas pipe to deliver flow measurement. These come pre-assembled and ready to install including the Orifice Union and Orifice Plate with up & down stream pipe sections. Our meter runs are being used in a range of industries from oil and gas to utilities and nuclear.

Meter Run Sections

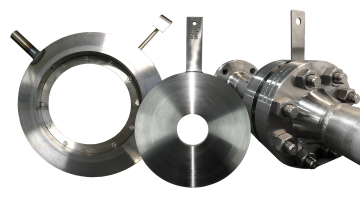

- Compatible Orifice Plates

- Square Edge

- Conical Entrance

- Quadrant

- Eccentric

- Segmental

- Restrictions

- Integral Orifice Carriers

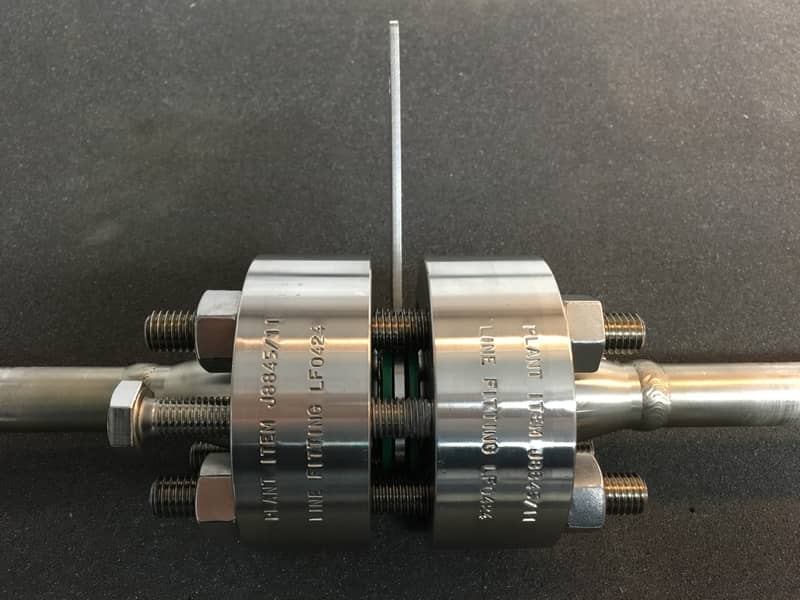

- Orifiice Union section

Full Orifice Meter Run

Specifications

Orifice Meter runs can be designed to suit a range of applications:

- Measurement of gases, steam, liquids and slurries

- Many options for materials of construction*

- 3.1 or 3.2 Materials Traceability & NACE Compliance

- ¼”NB 48″NB [DN8 to DN1200]

- ASME, API, PN Rated Process connection to suit all requirements

- Design Pressures & Temperature to customer requirement

- Non-Destructive Testing

- Calibration

- PED Compliance

Materials

- Carbon Steel grades

- ChromeMoly Steels (F9, F11, F22, F91 etc.)

- Austenitic Stainless Steel Grades (300 Series: 316, 304, 310 etc.)

- Duplex/Super Duplex Grades (F51, F53, F55 & F60)

- High Moly Stainless Steel (F44)

- Hastelloys (C22 / C276 / B3)

- Inconel® Grades (Alloy 600 / Alloy 625 / Alloy 718)

- Incoloy® Grades (Alloy 800 / Alloy 825)

- Monel® (Alloy 400)

- Cupronickel

- Titanium

- Tantalum, Zirconium