Non Destructive Testing

NDT Solutions

EMI offer an extensive range of Non Destructive Testing services including Hydrostatic Pressure Testing (ASME B16.5/PED), Dye Penetration (DPI) / Magnetic Particle Inspection (MPI), Positive Material Identification (PMI), Radiography of welds, Ferrite Checks and Ultrasonic Testing

Dye Penetration Testing

- Shows defects that might result in failure

- Quick, inexpensive and reliable

- Able to detect minor imperfections on material surfaces

- We are able to test large and small parts with complex shapes

Positive Material Identification

- Accurate material confirmation

- Quick, inexpensive & reliable

- Material report generated

- Multi element analysis or large & small surfaces

- Can be done at any stage of production

Ultrasonic Thickness Testing

- Able to measure otherwise inaccessible areas

- Logged results

- Measure thickness 0.6mm to 508mm

- Inaccessible and accessible areas

Hydrostatic Pressure Testing

- Test above operating conditions

- Physical testing to support calculations

- ASME BPVC/EN PD standards

- Up to 1000barg

- Internal & External Pressure

- Testing of any products that will hold pressure

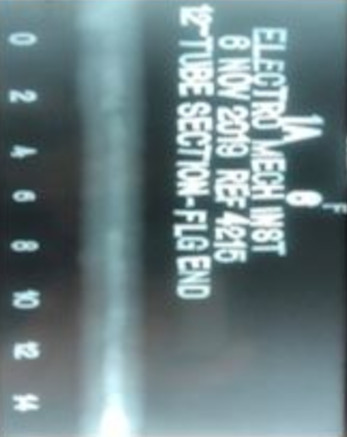

Radiography Testing

- Allows detailed inspection of welds

- Shows defects that may result in future failure

- Full penetration welds

- Detects defects in solid materials e.g. Pores & cracks

- When inspection is required below material surface

Material Testing Capabilities

Specifications

Testing

- Hydrostatic Pressure Testing (ASME B16.5/PED)

- Dye Penetration (DPI) / Magnetic Particle Inspection (MPI)

- Positive Material Identification (PMI)

- Radiography of welds

- Ferrite Checks

- Ultrasonic Testing

Other Services we can offer:

- Spark Erosion

- Wire cutting

- Coating/Painting

- Galvanising

- Polishing

- Additive Manufacturing

- 3D Printing