Material Testing Coupons

Material Coupon Preparation

EMI guarantee quality preparation of test coupons to specific customer requirements. Our range of machining and skilled engineers ensure that all coupons are machined to the highest standard reducing variation between samples to give the most accurate results from the material tests.

We create bespoke jigs, holding fixtures and loading blocks for your material tests to be carried out and can also provide welding services for metals, pipes and production of coupons for weld integrity testing.

Material Coupon Preparation

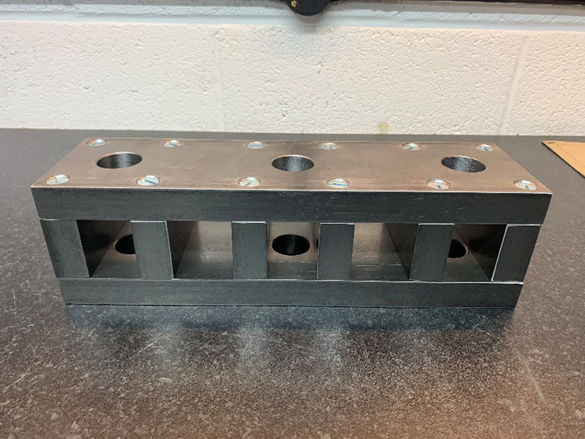

- 4 point Bend Coupons

- Peek insulation for 4 point bend testing loading blocks

- Pitting / crevice coupons

- Tensile Test Coupons (Strain Gauges and SSRT / Sub NACE)

- C-clamps stress testing of pipe section

- Rotating Cylinder Electrode (RCE) coupon

Type of tests we prepare for

- Mechanical

- Tensile Test

- Impact Test

- Bend Fracture Test

- Corrosion

- Chemical resistance tests

- Environmental stress

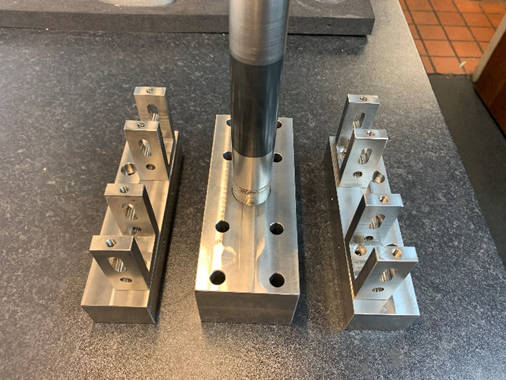

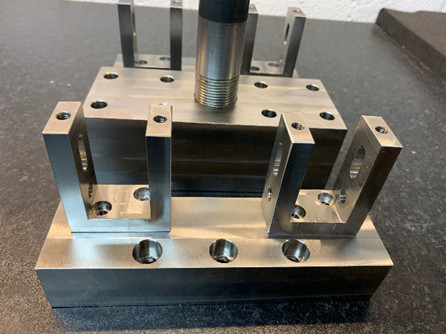

Material Coupon Test Jig

Hastelloy Test Jig Fabrication

Hydrogen Stress Cracking Test Jig

FAQs

Who do we work with?

EMI currently supply:

- Intertek Corrosion and Materials Consultancy (Formerly CAPCIS)

- Baker Hughes

- Rawwater Engineering Company

Materials

- Carbon Steel grades

- ChromeMoly Steels (F9, F11, F22, F91 etc.)

- Austenitic Stainless Steel Grades (300 Series: 316, 304, 310 etc.)

- Duplex/Super Duplex Grades (F51, F53, F55 & F60)

- High Moly Stainless Steel (F44)

- Hastelloys (C22 / C276 / B3)

- Inconel® Grades (Alloy 600 / Alloy 625 / Alloy 718)

- Incoloy® Grades (Alloy 800 / Alloy 825)

- Monel® (Alloy 400)

- Cupronickel

- Titanium

- Tantalum, Zirconium