Precision Engineering in Stockport Since 1967

We are a UK precision engineering firm based in Stockport in the North West of England that specialises in the manufacture and fabrication of quality process instrumentation and bespoke products. Founded in 1967, the company has a 50+ year proven track record supplying products and fast track solutions to the Chemical, Oil & Gas, and Pharmaceutical industries. More recently we have been providing instrumentation components for the Nuclear sector.

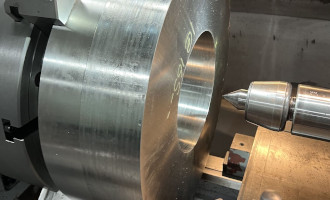

We are dedicated to satisfying our customers and committed to continuous improvement through strategic investments. Recently the business has had some substantial investments refurbishing our premises, new machinery and additional skilled and technical staff giving the company the ability to offer our customers the best possible engineering services and products.

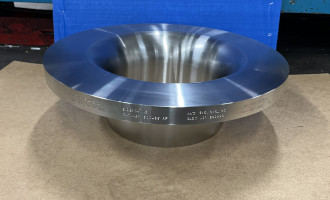

Precision Engineering Products

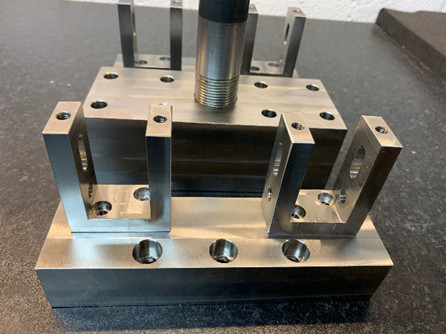

EMI provide bespoke products for extreme environments customised to meet customer requirements. All products are manufactured to the highest standards.

Our Expertise

We have gained a reputation for exceptional engineering competence providing over 50 years’ worth of manufacturing consistently high-end quality products and services to the Chemical, Oil & Gas and Pharmaceutical industries.

Our Capabilities

Uniquely positioned to offer a complete bespoke service from product evaluation, design, and testing, right through to precision component manufacture and delivery.

Our Clients

Why partner with EMI?

EXCEPTIONAL SERVICE

We pride ourselves in offering the best possible service to our customers from precision design concept through to delivery and beyond.

QUALITY PRODUCTS

EMI’s focus on quality is why our customers come back to us every time for precision engineered products that are resistant to a range of harsh environmental factors.

PROVEN TRACK RECORD

The company has a 50 year proven track record supplying precision engineered solutions into the Chemical, Oil, Gas, Water and Nuclear Industries.

HIGHEST STANDARDS

EMI is uniquely positioned to offer a complete bespoke service from product evaluation, process design, testing, right through to component manufacture, and delivery.

Precision Engineering FAQs

What is precision engineering, and why is it important in industrial fluid measurement?

Precision engineering involves the meticulous design and manufacture of components that require high accuracy and tight tolerances. In industrial fluid measurement, precision engineering ensures that devices like flow nozzles, orifice plates, and thermowells provide accurate and reliable readings, which are crucial for maintaining operational efficiency, safety, and regulatory compliance.

Which industries benefit from EMI’s precision engineering services?

EMI’s precision engineering services cater to a wide range of industries, including oil and gas, chemical processing, pharmaceuticals, water treatment, and energy. These industries rely on accurate fluid measurement and durable materials like Hastelloy, Tantalum, Aluminium, and Stainless Steel for their high-performance equipment.

What are the benefits of using Hastelloy and Tantalum in industrial components?

Hastelloy and Tantalum are materials known for their excellent resistance to corrosion and high temperatures. Hastelloy is often used in chemical processing environments due to its ability to withstand aggressive chemicals, while Tantalum is ideal for applications requiring high corrosion resistance, such as in heat exchangers and reactors.

Can EMI manufacture bespoke fluid measurement solutions?

Yes, EMI specialises in creating bespoke fluid measurement solutions tailored to customer requirements. Whether you need custom flow nozzles, thermowells, or bypass chambers, EMI’s precision engineering team can design and manufacture components to meet specific needs, ensuring optimal performance in any industrial environment.

What types of materials can EMI work with for custom manufacturing?

EMI has expertise in working with a wide range of materials, including Hastelloy, Tantalum, Aluminium, and various grades of Stainless Steel. These materials are chosen based on the specific demands of the application, such as resistance to corrosion, high-temperature performance, and mechanical strength.

How does EMI ensure the accuracy of their fluid measurement products?

EMI uses advanced CNC machining, rigorous quality control processes, and precise calibration techniques to ensure the accuracy of all their fluid measurement products. Additionally, the use of high-quality materials such as Hastelloy and Stainless Steel ensures durability and consistent performance over time.

Are EMI’s precision-engineered products suitable for high-pressure and high-temperature applications?

Yes, EMI’s precision-engineered products, such as thermowells, flow nozzles, and orifice plates, are designed to handle high-pressure and high-temperature environments. The use of materials like Hastelloy and Tantalum allows these products to perform reliably under extreme conditions.

How does EMI ensure compliance with industry standards for precision engineering?

EMI adheres to the highest industry standards and regulations, including ISO certifications and material certifications like EN10204. This ensures that every product manufactured by EMI meets the required performance and safety standards for demanding industrial applications.